When Power Failure Meets Life-Saving Equipment

Just how important is consistent electricity to healthcare?

As medical equipment floods low- and middle-income countries, there is an urgent need to ensure those investments generate the intended health impacts. However, very little data exists to appropriately address a country’s context and barriers to equipment use, including reliable power infrastructure, trained staff, continuous maintenance, and robust supply chains. These often unmet needs run the risk of generating massive equipment graveyards, especially in Sub-Saharan Africa. We know health impacts rely on more than a successful ColdTrace installation. A strong system depends on an entire ecosystem of health workers, the availability of parts and consumables, and the reliability of grid power or alternatives. Without these parts working in harmony, intended health impacts go unrealized, equipment falls into disuse, and the vital roles of healthcare workers go unsupported.

In early 2020, Nexleaf Analytics launched the Medical Equipment Program. The exploratory study aimed to identify barriers to equipment use. One of the critical barriers to providing high-quality care in health facilities is unreliable power. The program studied newborn units within selected county referral hospitals in Kenya.

Thanks to partnerships with Global Health Labs, Inc., a nonprofit organization created by Gates Ventures and the Bill & Melinda Gates Foundation, and through conversations with country partners and multinational organizations, Nexleaf embarked on ten months of data collection. The goal–to examine barriers to equipment utilization.

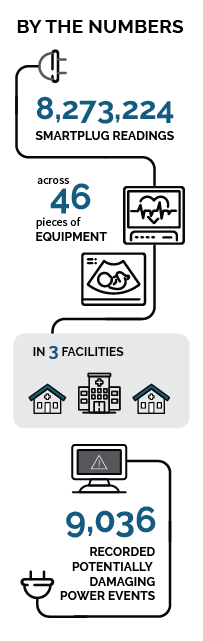

Three facilities whose power we monitored experienced an average of ten hours without power during the observation period. But even when facilities had power, they experienced 9,036 power quality events that had the potential to damage equipment. Those events produced a total of 2,877 hours of potential damage to equipment, an average of 40 days per facility.

In most cases, no single event is the sole cause of equipment failure; the problem lies in the combined quantity and severity of events. This persistent strain on equipment likely shortens its expected lifespan and degrades its built-in features’ ability to protect the equipment. We found that facilities are well aware of their power quality problems, see these problems as a significant source of damage to equipment, and have identified many ways to use power quality data to better advocate for their facility’s needs.

As we move into the next phase of the program, we are engaging in conversations with upper-level decision-makers to see where data can achieve maximum impact.

One thing is clear: we must work to ensure that these investments yield long-term benefits—in terms of equipment performance and health impacts.